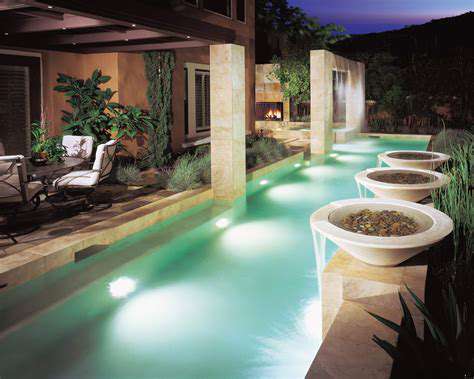

Where to place water fountains for positive flow

Practical Considerations for Maintenance and Safety

Maintenance Scheduling and Planning

Effective maintenance scheduling and planning is crucial for minimizing downtime and maximizing equipment lifespan. Careful consideration must be given to the frequency of inspections and repairs, ensuring that they are performed at optimal intervals to prevent catastrophic failures. This proactive approach not only extends the operational life of equipment but also reduces the risk of unexpected breakdowns, leading to significant cost savings and improved operational efficiency. A well-defined schedule allows for the allocation of resources, including personnel and parts, ensuring that maintenance tasks are completed in a timely and organized manner.

Planning should also involve a thorough assessment of potential risks and vulnerabilities. This includes identifying critical components, assessing their failure modes, and developing contingency plans to mitigate potential disruptions. Proactive risk management is paramount to achieving reliable operations and minimizing the impact of unforeseen events. Comprehensive documentation of maintenance procedures, including detailed instructions and diagrams, is essential for ensuring consistent and accurate execution by all involved personnel.

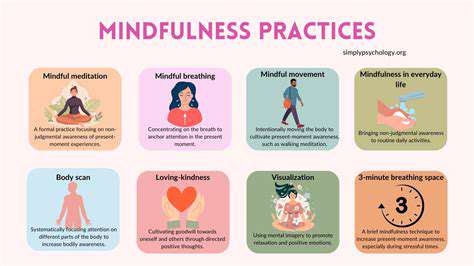

Personnel Training and Skill Development

Adequate training and skill development are critical for maintaining high standards of maintenance work. Employees need to be proficient in the use of specialized tools and equipment, as well as the proper techniques for performing various maintenance tasks. This not only ensures efficient and effective repairs but also minimizes the risk of accidents and injuries. Regular training sessions, workshops, and on-the-job mentoring programs can equip personnel with the necessary knowledge and expertise to handle complex maintenance challenges effectively.

Investing in ongoing training programs not only improves the quality of maintenance work but also enhances the overall skillset of the workforce, leading to a more productive and knowledgeable team. This continuous improvement approach can foster a culture of proactive maintenance, where employees are empowered to identify potential issues and contribute to preventive maintenance strategies. Furthermore, clear communication channels and readily available resources, such as manuals and online training modules, can further support the development of skilled maintenance personnel.

Equipment and Resource Management

Effective equipment and resource management is paramount for successful maintenance operations. This involves careful inventory management of spare parts, tools, and materials, ensuring that readily available supplies can meet the demands of any scheduled or unscheduled maintenance tasks. A well-maintained inventory system facilitates quick access to needed items, minimizing disruptions to the maintenance process. Regular audits and proactive replenishment strategies are essential to prevent delays and ensure that critical parts are always on hand.

Optimization of equipment usage through regular performance monitoring and analysis is also a critical aspect. Identifying potential equipment issues early on can prevent costly breakdowns and ensure optimal performance. Implementing predictive maintenance strategies, leveraging data analytics and sensor technology, can significantly improve the efficiency and effectiveness of maintenance operations. This data-driven approach allows for proactive intervention, minimizing downtime and maximizing the operational lifespan of equipment.